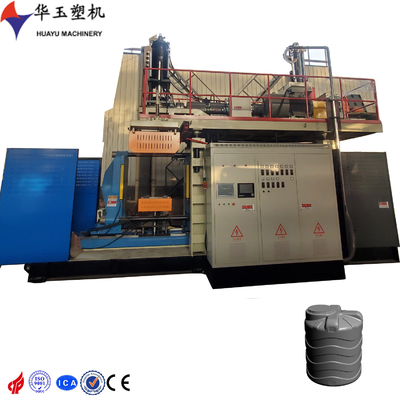

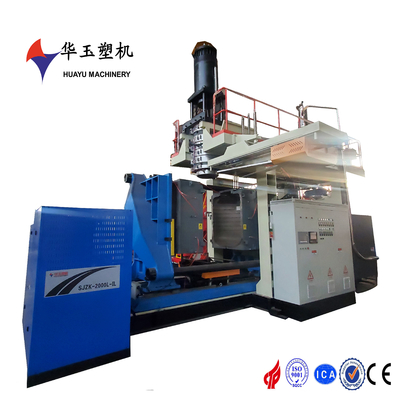

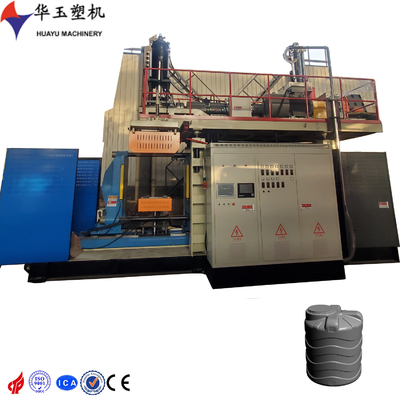

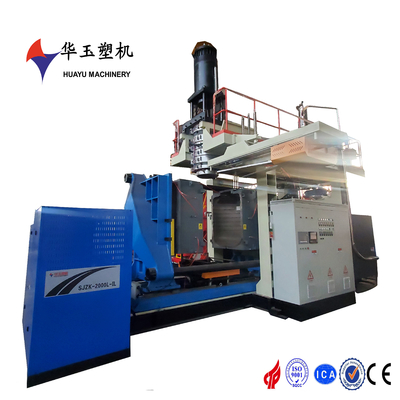

3000L 9-Layer Large Eco-Friendly Water Tank Blow Molding Machine with Purification Cooling System

| Herkunftsort | CHINA |

|---|---|

| Markenname | HUAYU |

| Zertifizierung | ISO9001 CE |

| Modellnummer | Hybm3000-9 |

| Min Bestellmenge | 1 Set |

| Preis | 440000 USD |

| Verpackung Informationen | für den Containertransport in viele Teile zerlegt werden |

| Lieferzeit | 4 Monate |

| Zahlungsbedingungen | L/c, t/t |

| Versorgungsmaterial-Fähigkeit | 1 Satz 120 Tage |

| Maschinendimension | 8.5 mal 6 mal 7.2 | Farbe | Gewohnt |

|---|---|---|---|

| Schicht | 2 Schichten | Produktpalette | 1000l |

| Gesamtleistung | 560 kW | Ausstellungsraum Ort | Keiner |

| Material | HDPE | Wasserdruck abkühlen | 0,3-0,6mpa |

| Reichweite | Behälter 1000L IBC | Automatisierung | Automatisch |

| Maschinen -Testbericht | Bereitgestellt | Touch-Screen | Siemens |

| Fütterungstyp | Vakuumzufuhr | Akkumulator-Kapazität | 35 kg |

| Mian-Ölpumpe | Getriebepumpe 160cc | ||

| Hervorheben | 3000L eco-friendly water tank machine,9-layer blow molding water tank machine,water tank machine with cooling system |

||

Focused on sustainability, this 3000L capacity blow molding machine with 9-layer co-extrusion features a water tank system that ensures clean and efficient cooling water circulation. This eco-friendly design reduces environmental impact and enhances the machine's longevity. The machine is equipped with advanced technologies for precise temperature control and consistent product quality, making it an excellent choice for environmentally conscious manufacturers. The water tank is designed for easy maintenance and long-term reliability, making this machine a cost-effective and efficient solution for your production needs.

|

die head |

||

|

Accumulator capacity |

150kg |

designed by ourselves and get the patent |

|

Die diameter |

According to products |

|

|

ie head heating power |

160kw |

|

|

Clamping System |

||

|

platen size |

2400*2500*70mm(W*H*T) |

smooth running, no noise; the clamping force is big |

|

clamping cylinder |

350+200*2 |

|

|

clamping cylinder stroke |

2200mm |

|

|

clamping force |

3000KN |

|

|

distance between platens |

1600-4000mm |

|

|

max. mould size |

1800*2500mm(W*H) |

|

![]()