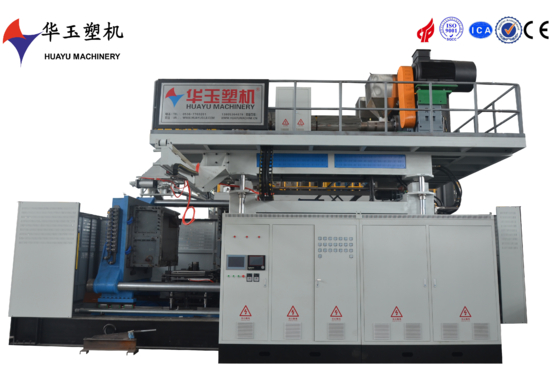

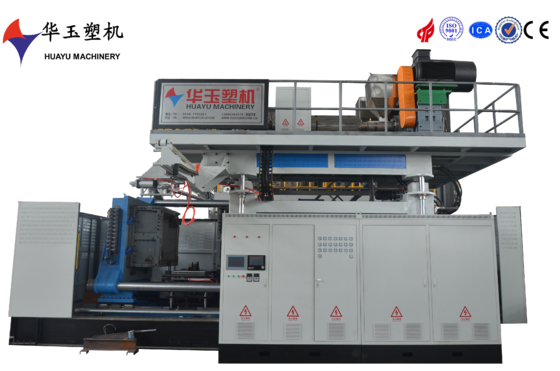

5000L 2-Layer Large Intelligent Water Tank Blow Molding Machine with Intelligent Control System

| Herkunftsort | CHINA |

|---|---|

| Markenname | HUAYU |

| Zertifizierung | ISO9001 CE |

| Modellnummer | HYBM5000-2 |

| Min Bestellmenge | 1Set |

| Preis | 380000 USD |

| Verpackung Informationen | für den Containertransport in viele Teile zerlegt werden |

| Lieferzeit | 4 Monate |

| Zahlungsbedingungen | T/t, l/c |

| Versorgungsmaterial-Fähigkeit | 1 Satz 120 Tage |

| Typ der Blasformung | Einspritzungs-Blasen | Heizleistung schrauben | 4.4kw*24 |

|---|---|---|---|

| Parison | MOOG 200 Punkte | Reinigungsmethode | Einfache Reinigung |

| Gesamtgewicht | 58T | Anwendung | Wasserbehälterproduktion |

| Klemmzylinder | 350+200*2 | TATAOL POWER | 290 |

| Automatisierungsnote | Automatisch | Produkt | 500-2000L Kunststoffprodukt |

| Hydrauliköldichtung | DZ | Extrudermotor | 75 kW*4 |

| Produktionsgeschwindigkeit | 100 bis 200 Stück/h | Klemmkraft | 200t |

| Maschinendimension | 15*9*11 | ||

| Hervorheben | 5000L water tank blow molding machine,intelligent control water tank machine,2-layer large water tank machine |

||

This intelligent blow molding machine with a 5000L capacity and 2-layer co-extrusion is designed for smart production processes. The water tank system ensures efficient cooling and heat dissipation, maintaining optimal operating temperatures and enhancing production efficiency. The machine's smart control system includes real-time monitoring and diagnostics, ensuring optimal performance and quick troubleshooting. Its precision engineering and high-quality components make it a reliable choice for producing large, multi-layered plastic products. The water tank is designed for easy maintenance and long-term reliability, making this machine a cost-effective and efficient solution for your production needs.

|

Auto Feeder |

||

|

hopper material |

stainless steel |

Stable performance, easy maintenance |

|

feeding type |

spring loaded |

|

|

feeding motor |

2.2/2.2/2.2/2.2kw |

|

|

Extrusion System |

||

|

Screw diameter |

110/110/110/110mm |

Nitrided 38CrMoAIA |

|

Screw L/D ratio |

28:1 |

special designed screw can ensure the material plasticizing uniform and efficient |

|

Extruder motor |

75/75/75/75kw |

|

|

Reducer |

315/315/315/315 |

Best quality brand in china ,long life and low noise |

|

Screw heating power |

4.4kw*16 |

|

|

Plasticizing capacity |

800kg/h |

|

![]()