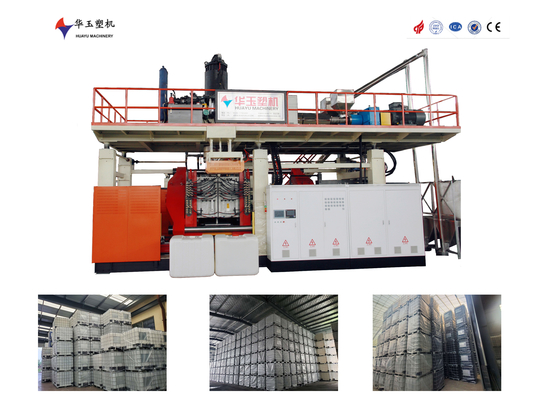

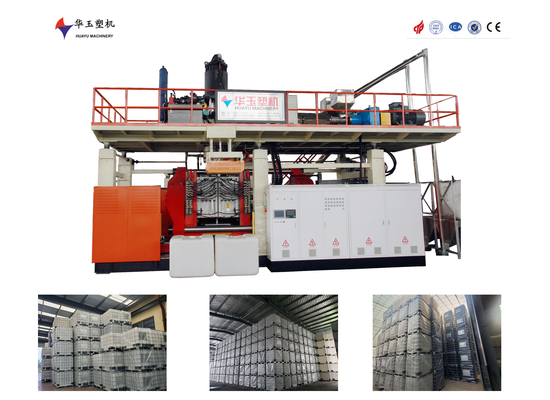

1000L zweischichtige große Schwerlastwasserbehälter-Blow-Formmaschine

| Herkunftsort | CHINA |

|---|---|

| Markenname | HUAYU |

| Zertifizierung | ISO9001 CE |

| Modellnummer | HYBM1000-2 |

| Min Bestellmenge | 1 Set |

| Preis | 160000 USD |

| Verpackung Informationen | für den Containertransport in viele Teile zerlegt werden |

| Lieferzeit | 4 Monate |

| Zahlungsbedingungen | T/t, l/c |

| Versorgungsmaterial-Fähigkeit | 1 Satz 120 Tage |

| Größe | Angepasst | Schraubfassmaterial | 38CrMoAlA, Nitrierung |

|---|---|---|---|

| Reinigungsmethode | Einfache Reinigung | Reichweite | Behälter 1000L IBC |

| Schichten | 5 Schichten | Heizleistung schrauben | 5.5kw*12 |

| Plattenabstand | 1100-2500mm | Stromspannung | 220 V/380 V |

| Jahr | 2024 | Motor | Siemens |

| Maschinendimension | 12*11*7,5M | Mian-Ölpumpe | Getriebepumpe 160cc |

| Produktpalette | 1000l | Plc | Siemens |

| Farbe | Gewohnt | ||

| Hervorheben | 1000L Wasserbehälter Blasformmaschine,heavy-duty water tank molding machine,Zwei-Schicht-Wasserbehälter-Blow-Molder |

||

Diese zweischichtige 1000-Liter-Schwerlast-Blasformmaschine ist für die Herstellung hochwertiger mehrschichtiger Kunststoffprodukte ausgelegt.Das zweischichtige Co-Extrusionsystem ermöglicht eine höhere Materialflexibilität und eine verbesserte ProduktleistungDas schwere Kühlsystem des Wasserbehälters sorgt für eine effiziente Wärmeableitung und eine optimale Betriebstemperatur, wodurch die Produktionseffizienz erhöht wird.Das fortschrittliche Steuerungssystem der Maschine ermöglicht eine präzise Steuerung des FormenprozessesDurch sein langlebiges Design und seine zuverlässige Leistung eignet es sich für Industriezweige, die große, mehrschichtige Kunststoffprodukte benötigen.Das Wassertanksystem ist für eine einfache Wartung und langfristige Zuverlässigkeit ausgelegt, so dass diese Maschine eine kostengünstige und effiziente Lösung für Ihre Produktionsanforderungen darstellt.

|

Klemmen System |

||

|

Plattengröße |

1700*1800*70- Ich bin nicht hier. |

ein reibungsloses Laufen, kein Lärm; Die Klemmkraft ist groß |

|

Klemmzylinder |

300 |

|

|

Zylinderverschluss |

1800mm |

|

|

n-Kraft |

1000KN: |

|

|

Abstand zwischen den Platten |

900 bis 2700mm |

|

|

Max. Formgröße |

1500*1700(Mann und Frau) |

|

|

Blas- und Kühlsystem |

||

|

Schlaganfall |

je nach Erzeugnissen |

|

|

Auf-/Abschlag von Blasspin |

600mm |

|

|

ir Sitzstrich |

400 mm |

|

|

Höchstluftdruck |

0.8Mpa |

|

|

Luftverbrauch |

1.5 m3/min |

|

|

Kühlmethode |

Umlaufwasser |

|

|

Wasserdruck |

0.3MPa |

|

|

Kühlwasserverbrauch |

3 m3/h |

|

![]()