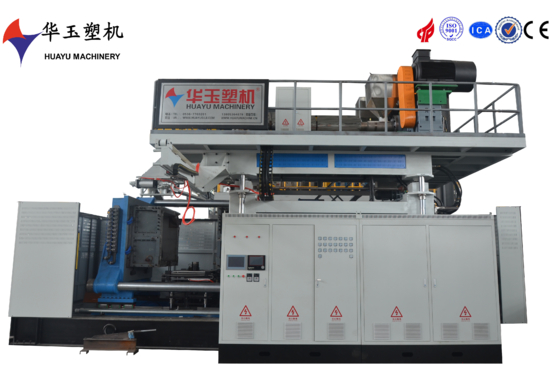

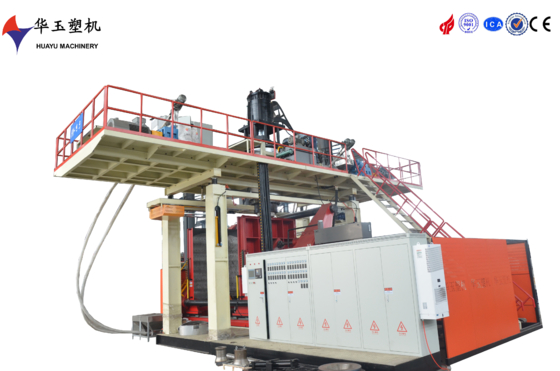

3000L 2-Schicht Groß-Hochleistungs-Wassertank-Blasformmaschine

| Herkunftsort | China |

|---|---|

| Markenname | HUAYU |

| Zertifizierung | ISO9001 CE |

| Modellnummer | HYBM3002 |

| Min Bestellmenge | 1 Satz |

| Preis | 290000 USD |

| Verpackung Informationen | für den Containertransport in viele Teile zerlegt werden |

| Lieferzeit | 4 Monate |

| Zahlungsbedingungen | T/T, L/C |

| Versorgungsmaterial-Fähigkeit | 1 Satz 120 Tage |

| Jahr | 2024 | Haltbarkeit | Exzellent |

|---|---|---|---|

| Maschinengröße | 5,0 x 2,4 x 3,8 m | Ausdehnen des Anschlags | je nach Erzeugnissen |

| Material | LDPE, HDPE, PP | Recyclingabilität | Recycelbar |

| Automatisierung | Vollautomatisch | Maximale Produkthöhe | 1500-2500 mm |

| Stromspannung | 380 V/50 Hz | Plattengröße | 2200*2400*70 mm |

| Maschinenprüfbericht | Bereitgestellt | Extruder-Motor | 37/37/37/37/37 kW |

| Extrudermotor | 110/90*2/15*3 | Extrudermotorleistung | 110 kW |

| Wasserdruck abkühlen | 0,3-0,6mpa | ||

| Hervorheben | 3000L Wasserbehälter Blasformmaschine,Hochleistungs-Wassertank-Formausrüstung,2-Schicht Groß-Wassertankmaschine |

||

Diese zweischichtige 3000L-Schwerlast-Blasformmaschine ist für die Herstellung mehrschichtiger Kunststoffprodukte mit verbesserter Haltbarkeit und Leistung ausgelegt.Das zweischichtige Co-Extrusionssystem ermöglicht fortschrittliche Materialkombinationen, die bessere Barriereeigenschaften und eine verbesserte Produktfestigkeit bieten.Verbesserung der ProduktionseffizienzDas fortschrittliche Steuerungssystem der Maschine bietet eine präzise Kontrolle über den Formprozess und sorgt für eine gleichbleibende Produktqualität.Sein langlebiges Design und seine zuverlässige Leistung machen es für Industriezweige geeignet, die großeDas Wasserbehältersystem ist für eine einfache Wartung und langfristige Zuverlässigkeit konzipiert, was diese Maschine zu einer kostengünstigen und effizienten Lösung für Ihre Produktionsanforderungen macht..

|

Automatische Zuführung |

||

|

Stoff für die Hopper |

Stahlaus rostfreiem Stahl |

Stabile Leistung, einfache Wartung |

|

Fütterungsart |

弹?? 料mit Federladen |

|

|

Zuführmotor |

2.2/2.2/2.2/2.2kW |

|

|

Extrusionssystem |

||

|

Schraubendurchmesser |

110/110/110/110mm |

Nitrierte 38CrMoAIA |

|

Schraub L/D-Verhältnis |

28:1 |

speziell konstruierte Schraube kann sicherstellen, dass das Material einheitlich und effizient plastisiert |

|

Extrudermotor |

75/75/75/75kW |

|

|

Verringerer |

315/315/315/315 |

Die beste Qualitätsmarke in China,lange Lebensdauer und geringer Lärm |

|

Schraubheizleistung |

4.4kw*16 |

|

|

Plastifizierungskapazität |

800 kg/h |

|

![]()