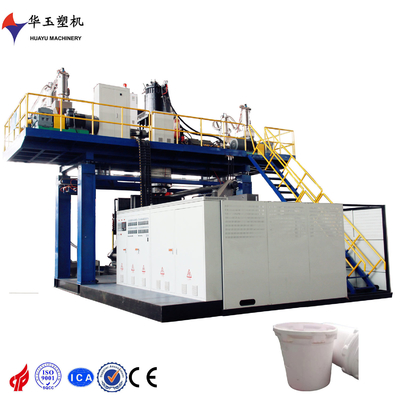

5000L Doppelschicht-Wasserbehälter mit großer Kapazität und Hochleistungs-Koextrusionsmaschine

| Herkunftsort | China |

|---|---|

| Markenname | HUAYU |

| Zertifizierung | ISO9001 CE |

| Modellnummer | HYBM5002 |

| Min Bestellmenge | 1 Satz |

| Preis | 380,000 USD |

| Verpackung Informationen | für den Containertransport in viele Teile zerlegt werden |

| Lieferzeit | 4 Monate |

| Zahlungsbedingungen | T/T, L/C |

| Versorgungsmaterial-Fähigkeit | 1 Satz 120 Tage |

| Stromquelle | Elektrisch | Luftschalter | Schneider |

|---|---|---|---|

| Extrudermotor | 110 kW | Maschinendimension | 12 mal 11 mal 8.5 |

| Maschinengewicht | 11,8T | Getriebe | Guomao |

| Garantie | 1 Jahr | Schichten | 2 Schichten |

| MOTOR | Siemens | Eimerstärke | nicht sehr dick |

| Produkt | Wasserbehälter,anderes Kunststoffprodukt | Gesamtgewicht | 100T |

| Fütterungsmotor | 11kw*2 | Schraubdurchmesser | 90/90/90/90 mm |

| Material | Kunststoff (typischerweise HDPE oder PP) | ||

| Hervorheben | 5000L Wassertank-Blasformmaschine,Zwei-Schicht-Wasserbehälter-Gießmaschine,Hochleistungs-Koextrusions-Blasformmaschine |

||

Diese 5000-Liter-Doppelschicht-Blasformmaschine ist für die Herstellung hochwertiger mehrschichtiger Wassertanks ausgelegt.Das zweischichtige Co-Extrusionssystem ermöglicht eine höhere Materialflexibilität und eine verbesserte ProduktleistungDas hochleistungsfähige Kühlsystem sorgt für eine effiziente Wärmeableitung und eine optimale Betriebstemperatur.Gewährleistung einer gleichbleibenden ProduktqualitätDiese Maschine ist für Industriezweige geeignet, die langlebige und zuverlässige mehrschichtige Wassertanks benötigen.

|

Automatische Zuführung |

||

|

Stoff für die Hopper |

Stahlaus rostfreiem Stahl |

Stabile Leistung, einfache Wartung |

|

Fütterungsart |

弹?? 料mit Federladen |

|

|

Zuführmotor |

2.2/2.2kW |

|

|

Extrusionssystem |

||

|

Schraubendurchmesser |

150/150mm |

Nitrierte 38CrMoAIA |

|

Schraub L/D-Verhältnis |

30:1 |

speziell konstruierte Schraube kann sicherstellen, dass das Material einheitlich und effizient plastisiert |

|

Extrudermotor |

160/160kW |

|

|

Schneller |

mit einem Durchmesser von |

Die beste Qualitätsmarke in China,lange Lebensdauer und geringer Lärm |

|

Heizleistung |

6KW*14 |

|

|

Plastifizierungskapazität |

1000 kg/h |

|

![]()